Pipe manufacturing

Best practise in Belgium

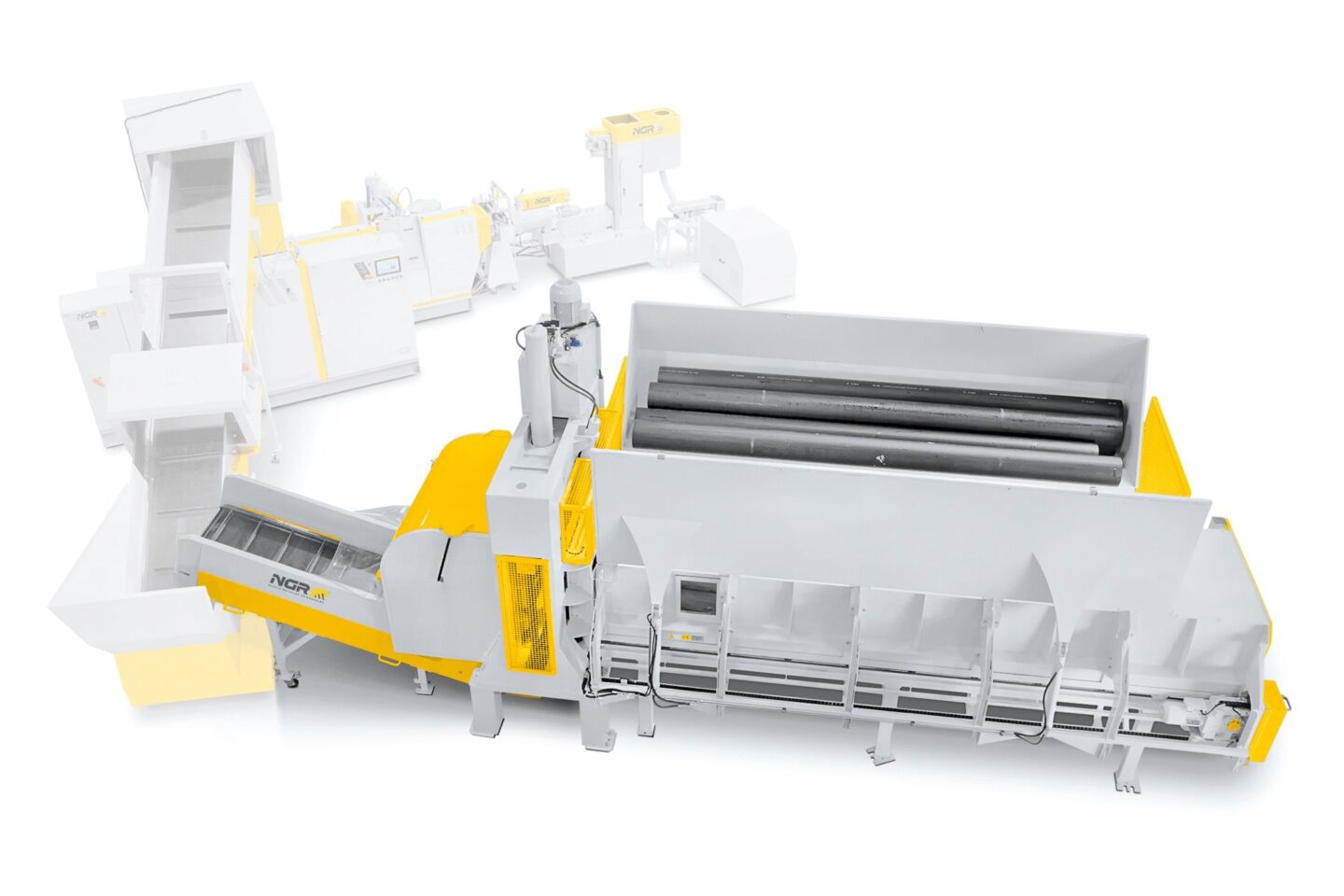

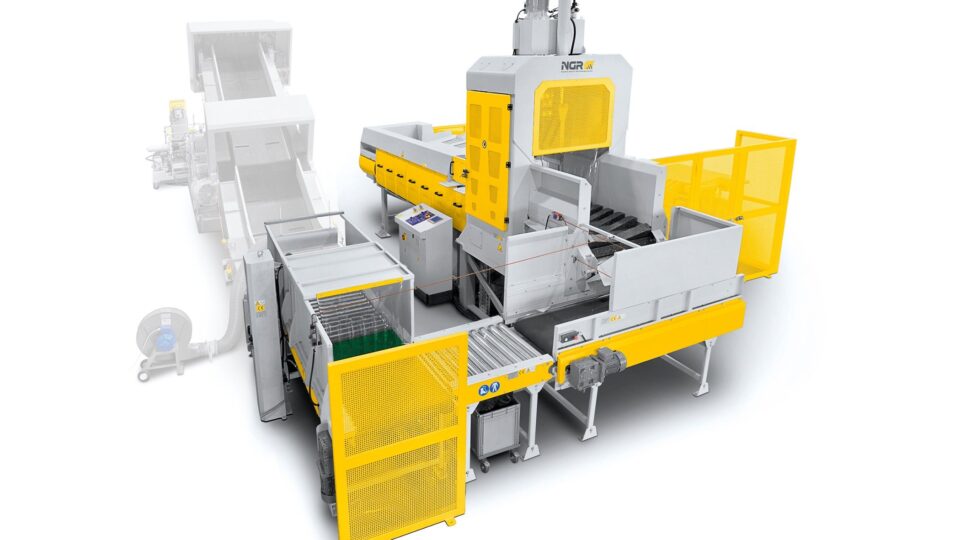

The customized NGR peripherals solution

After a charging hopper has been loaded with PE pipes with a length of 4,000 mm, the process circuit is started at the central control unit. The pipes are conveyed forwards hydraulically and cut into rings between 500 and 600 mm in size using a guillotine. Then they drop onto the conveyor belt of the downstream S:GRAN (shredder-feeder-extruder combination).

Starting material

HDPE/LDPE pipes with a length of 4,000 mm and a diameter of up to 400 mm

Requirements

- Easy material handling

- Size reduction

- Recycling (zero waste production without loss of material)